Bulletin 149: Gammon DP-Pilot

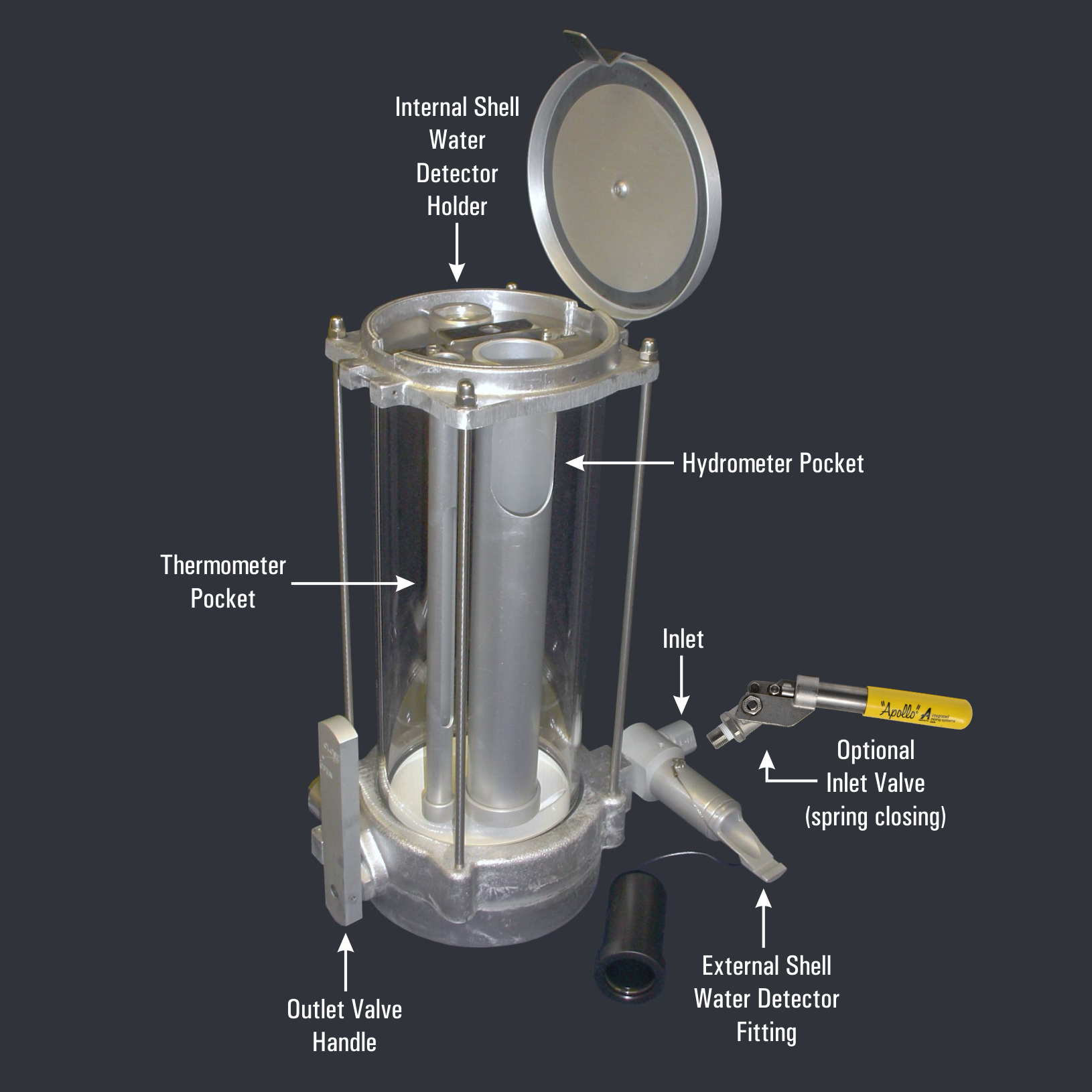

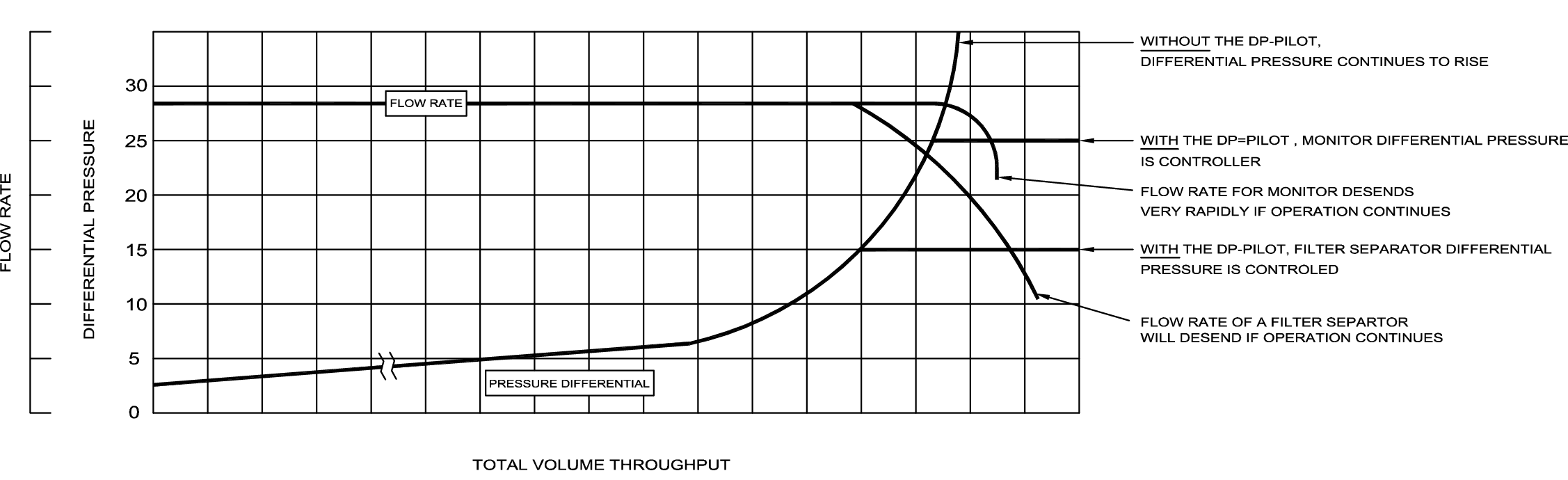

Many filter systems operate under the threat of a sudden influx of contamination that plugs the filter elements. Recently, water-absorbing elements have added to this concern. If no one is watching the differential pressure gauge at the time, you can burst the elements, with the dirt and debris going downstream and possibly into the aircraft. We designed the Gammon DP-Pilot so you can forget about element bursting or deck plate damage with any type of element, even the water absorbing elements.

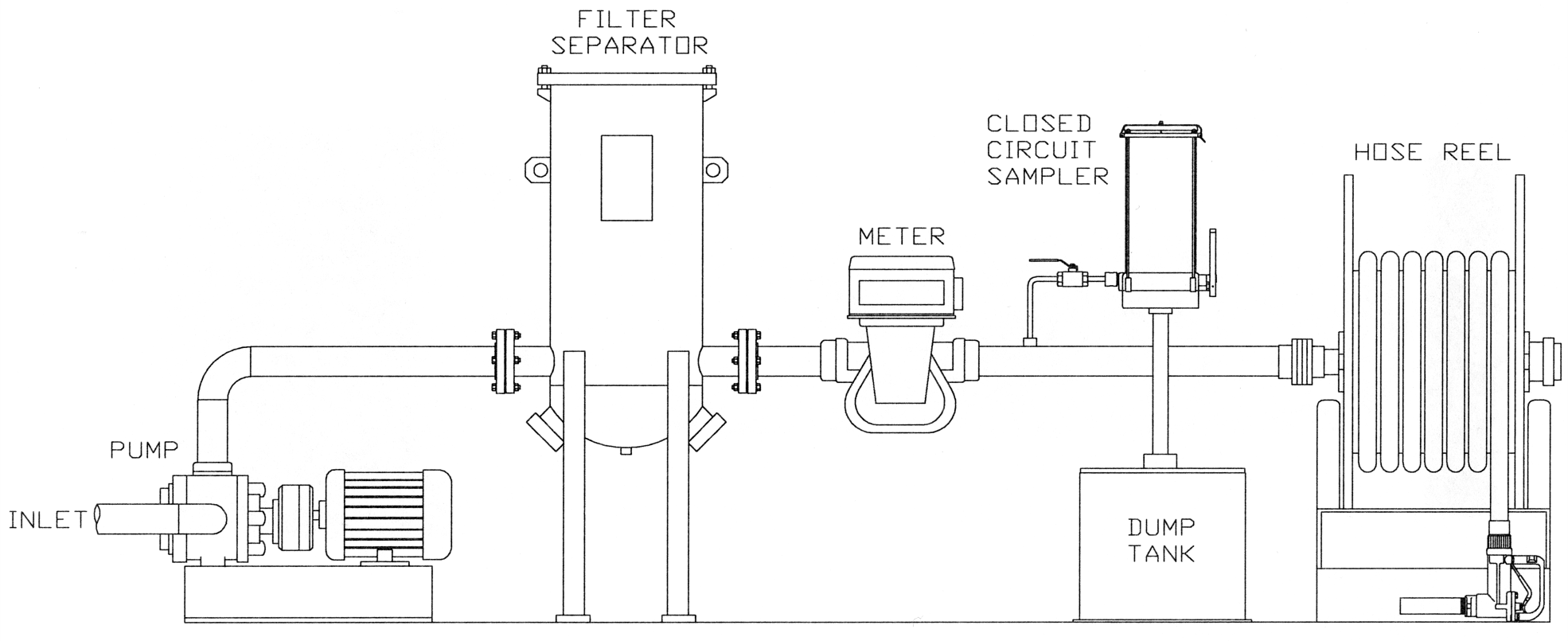

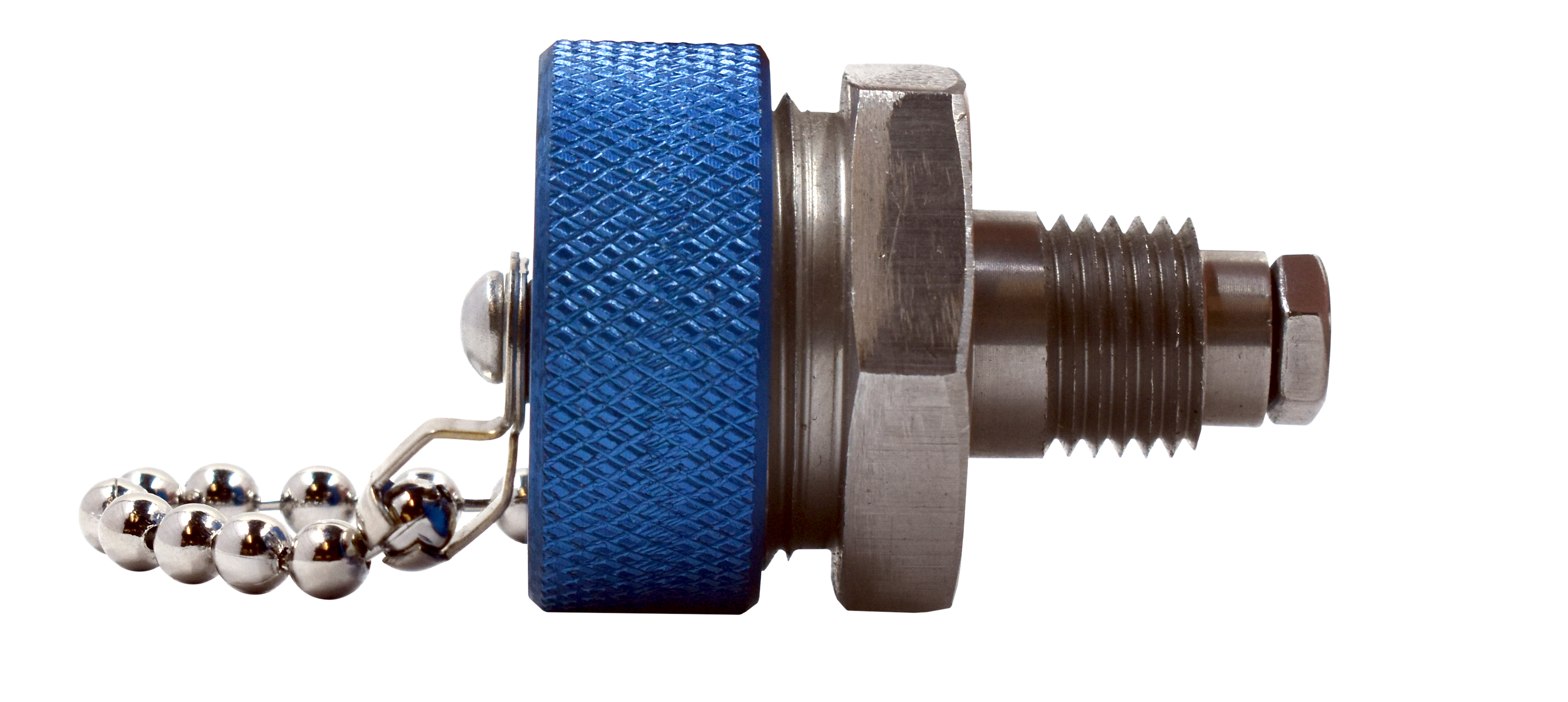

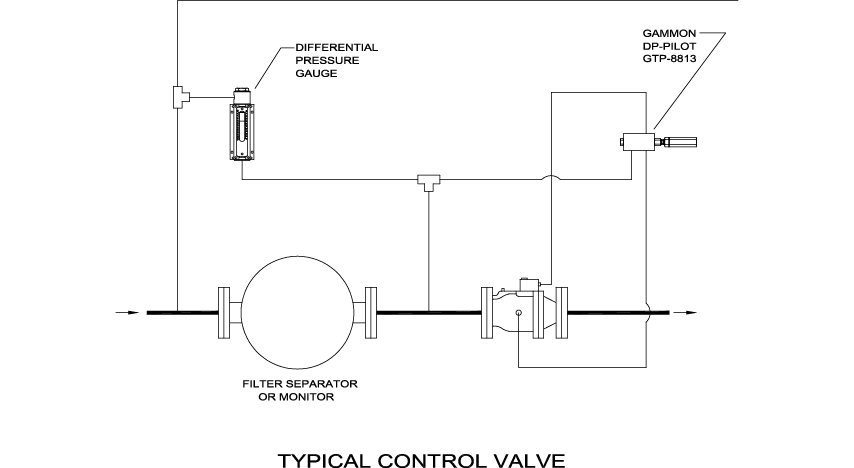

In 1995, we wrote GamGram 44 showing that high differential pressure concerns could be erased by a unique mounting of a rate of flow control pilot valve. The solution is simple and elegant. The pilot senses the pressure drop on a vessel and, if that pressure drop exceeds a set limit, the pilot takes over, lowering the flow rate. Because pressure drop decreases as flow rate decreases, the elements can never burst.

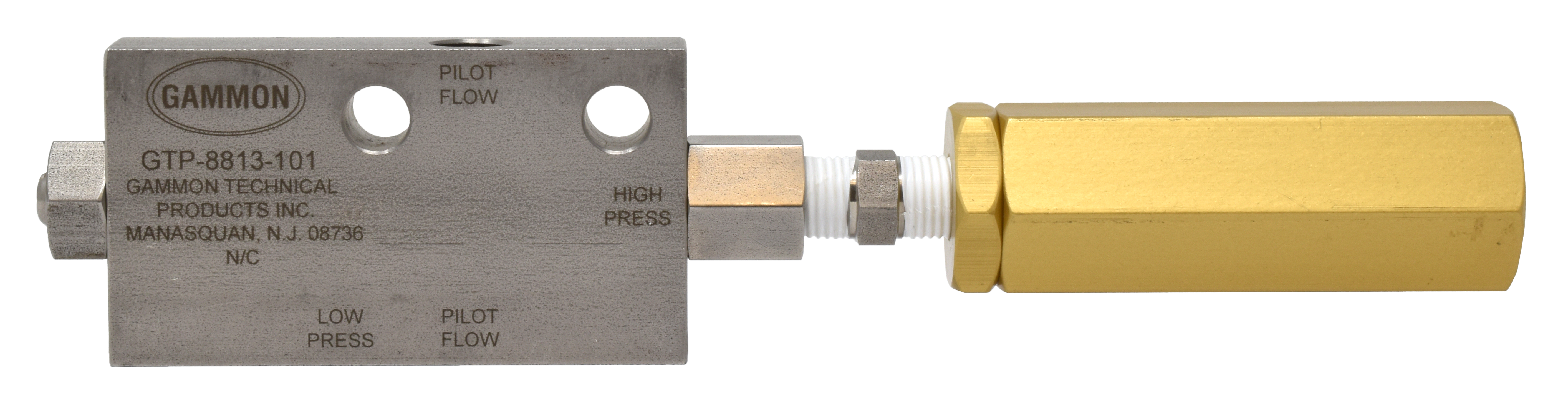

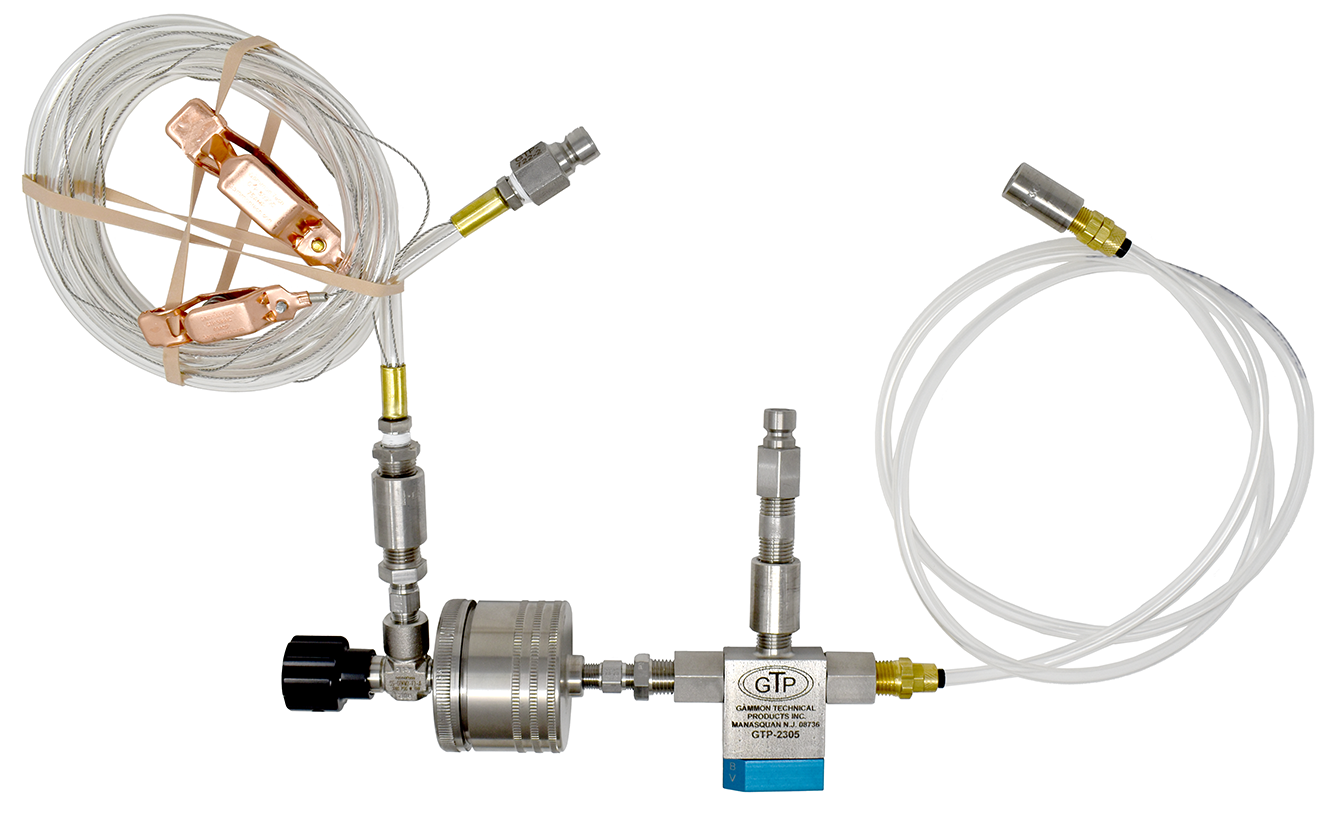

We have now designed an all stainless steel pilot specifically for this purpose, and we are proud to offer the Gammon DP-Pilot. The DP-Pilot field test was performed at a US Air Force facility in early 1998. Their primary concern was that water-absorbing elements could rupture or the deck plate in the vessel could deform or tear. As a result of that test, this pilot was designated as required equipment on all US Air Force refueler vehicles.

We ran the test starting at full flow rate. The DP-Pilot had no detrimental effect on the system. We then added water to plug the water-absorbing elements in this truck’s filter vessel. As the differential pressure increased, nothing happened until it reached 20 psid (differential), our set point (this is adjustable). At 20 psid, the DP-Pilot took over, slightly lowering the flow rate. This kept the differential pressure from exceeding the set point. As we added more and more water, the pilot dutifully closed the main control valve more and more, lowering the flow rate and maintaining the 20 psid pressure drop. At the end of the test, the meter was barely moving, less than 1 gpm, yet the pressure drop never exceeded 20 psid!

Will it work with prefilters and filter separators?

Yes. Any filter vessel in a system that has an in-line control or slug valve if it has a pilot circuit can accept a DP-Pilot. You can even add two DP-Pilots to a slug valve downstream of a prefilter and filter separator combination. One pilot protects the prefilter and the other protects the filter separator.

What pressure drop ranges are available?

Our standard set point is 20 psid. On the basic model, this is adjustable from 15 to 35 psid. Other springs are available for ranges from 1 to 50 psid.

What is the maximum working pressure?

We recommend the maximum working pressure of this pilot to be 450 psi. There is no minimum pressure, minimum flow rate, or maximum flow rate. The maximum temperature is 250°F.

What brands is it compatible with?

The Gammon DP-Pilot works with Cla-Val, Whittaker, Brooks, Oil Capitol, Smith, Haar, Avery Hardoll, or any other brand of piston or diaphragm in-line control valve if it has a pilot flow circuit.

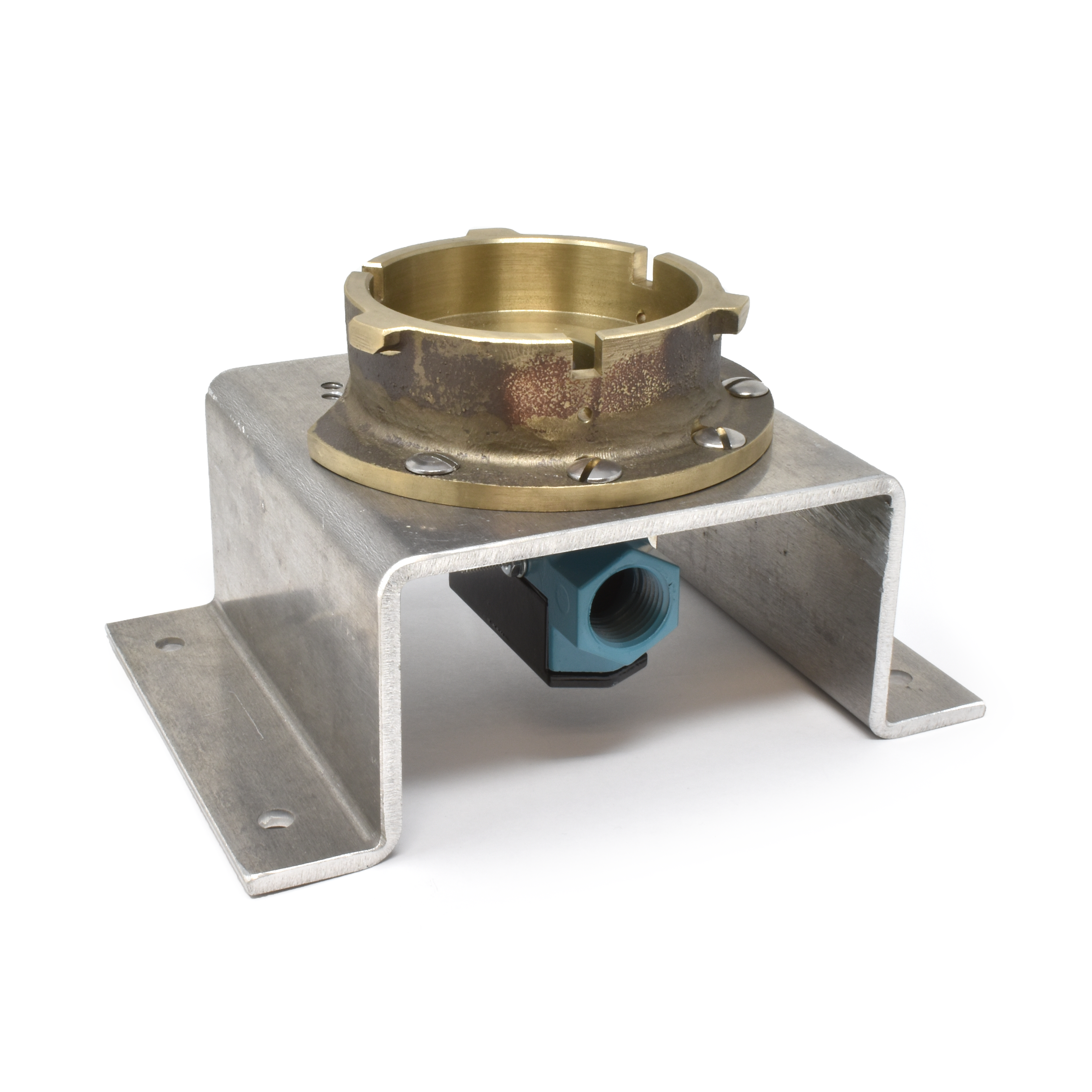

How is it installed?

Call us with your valve make and model number for an installation schematic.